Measuring Large Volume Parts with the O-Inspect 863 – Patterns in Calypso

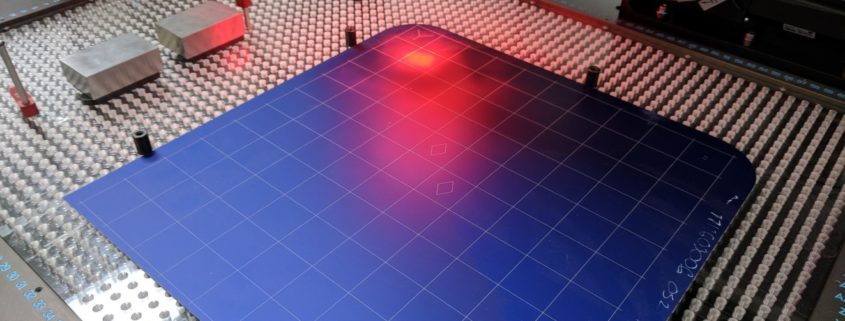

With the addition of our latest CMM, the Zeiss O-Inspect 863, we are now able to measure large volumes of parts with the high measurement accuracy that the system’s white light focal sensor, camera and scanning probe have to offer.

Patterning in the Zeiss Calypso software allows for measurements that are programmed onto a single part to be patterned to as many parts or features that can fit on the machine. A good illustration of this feature is shown by the measurement of grid points along a calibration plate. The customer required X and Y grid locations to be measured on a 10 by 10 laser etched plate. The O-Inspect Camera was used to create intersecting lines to measure these etches and a 10 row by 10 column pattern was implemented to instruct the program to measure all 100 points. The program outputs the point set for use in a certified report.

Patterning in the Zeiss Calypso software allows for measurements that are programmed onto a single part to be patterned to as many parts or features that can fit on the machine. A good illustration of this feature is shown by the measurement of grid points along a calibration plate. The customer required X and Y grid locations to be measured on a 10 by 10 laser etched plate. The O-Inspect Camera was used to create intersecting lines to measure these etches and a 10 row by 10 column pattern was implemented to instruct the program to measure all 100 points. The program outputs the point set for use in a certified report.

This feature does have certain limits. Measurement deviations must be within a range for the camera and white light sensor or the measurements will return empty and terminate the program. Parts must also be equally spaced when using the white light sensor as points may be taken off of the part surface. When ideal conditions are met this program feature can greatly cut down on measurement time, loading time and manual system input.

Leave a Reply

Want to join the discussion?Feel free to contribute!