Industrial X-Ray Inspection Services

3D Engineering Solutions X-Ray Inspection Services utilizes the best digital x-ray equipment available to deliver your digital and industrial radiography requirements. Our four Nikon X-ray equipment/CT machines and large technical staff allow us to deliver results with 24/7 service available for your more time-sensitive needs.

Industrial X-Ray Program Services

Our Industrial X-Ray equipment services include:

- Troubleshooting

- Non Destructive Testing

- Inspection Services

- Digital X-Ray Service

- Industrial Imaging

- PCB Inspection

- CT Scanning

Centrally located in the eastern half of the US to provide rapid industrial x-ray inspection services, 3DES is a one-stop-shop for your industrial X-ray and dimensional metrology needs. Our 10,000 square foot temperature-controlled lab space and 15,000 square foot warehouse is ideally suited for both high and low volume orders. With multiple docks and forklift capability to 6,000 lbs. we are set up to handle both your large and small requirements with our x-ray inspection services.

Industrial X-Ray Imaging Services

3D Engineering Solutions has experience scanning large quantities of parts under tight timeline requirements. Offering 24/7 quick turn processes and services utilizing multiple machines allows our customers to meet their objectives in a timely fashion.

Troubleshooting

We can even create live x-ray videos of your product as it is being actuated as well as still individual images with high image quality. We have the ability to run power, air, and hydraulics to your device to remotely activate it during x-ray inspection. These videos are a great troubleshooting technique and give you a real insight into the actual working of your devices under their assembled and loaded state. You will be able to visualize the source of your hard-to-find issues by being able to see through the walls of your product into the inner workings.

Non Destructive Testing (NDT)

X-ray unit inspection is a non-destructive testing method for looking inside of your parts and assemblies. Oftentimes, we do not even need to unpackage your products as standard packaging can be virtually invisible to the x-rays. When required, we have staff that can easily and efficiently repackage your product and even add X-ray inspection labels to confirm the product that has been inspected. You will be happy with our friendly and responsive x-ray program service.

Dimensional Measurement

Not only are you able to visualize the inner workings and shapes in your product, but you can also extract accurate dimensional measurements. We are able to carefully and precisely control the position of the product relative to the x-ray source and detector. Because of this, we are able to measure internal product dimensions and validate these with calibrated scaling artifacts positioned near the product. There are some limitations to this ability. However, most can be overcome to provide the internal and external dimensional measurements you need.

Digital Industrial Radiography

We use digital detectors to capture industrial imaging data from x-ray machines. Our high-resolution PerkinElmer 16-bit x-ray detectors are used to capture permanent digital copies of data from x-ray machines that can be indefinitely stored for future retrieval. These provide excellent resolution for all your x-ray inspection needs.

In addition to the standard black and white x-ray view, we are able to colorize the greyscales and show the data in color. Since the human eye can distinguish many more colors than grayscale points, using color to display data from x-ray machines allows one to better visualize some types of defects. These defects then are easier to visualize in our provided inspection reports.

All x-rays are available to our customers in the native TIFF, or JPG file formats for easy viewing.

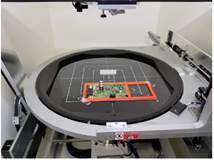

PCB Inspection

Our 160kV Nikon system is purpose-built for PCB (Printed Circuit Board) inspections. It employs industry-leading software to quickly and efficiently evaluate common PCB concerns such as semiconductor package voids, solder void analysis, BGA solder ball analysis, and more. Our staff is trained in proper ESD handling procedures. Allow us to program automatic inspection routines to capture data from even the most complicated boards.

Whether you have just a few sample boards to inspect for qualification purposes or an entire production run, 3D Engineering Solutions is there to provide you with outstanding service.

X-Ray Process Setup

For larger volumes of serialized parts, we implement process control and documentation through bar code readers when required. Individual x-ray images can be stored with the serialized information for future review, customer disposition, verification, or long-term storage. As required, labels can be added to products or containers indicating that the x-ray unit’s inspection has occurred. Rejected parts are separated and can be marked as needed.

We employ onsite 3D printing of custom fixtures for repeatable positioning of parts between scans. This allows your x-ray images to be displayed in the same orientation part after part. Each of our engineers is trained in one of our multiple CAD platforms and the use of our 3D printer to create custom polymer fixtures for their work. When a higher precision is required for large-scale work, Fixtures are machined to specification using outside suppliers.

We are also able to perform x-ray unit inspections to common standards including the inclusion of Image Quality Indicator (IQI) standards during scanning. We can accept and follow industry specifications that you provide.

X-Ray Systems

We offer service using both horizontal and vertical x-ray units. These industrial imaging x-ray machines offer superior definition and accuracy compared to their medical-grade counterparts. They range from 160kV nano focus, 225kV microfocus, and 450kV microfocus to cover the full range. Our 450kV system is the only microfocus system available and allows outstanding resolution over competitive mini-focus systems. These nano and microfocus systems have a very small spot size which allows a maximum resolution of all of your part’s edges and allows a cleaner look at potential defects. All of our industrial x-ray units employ high-resolution digital detectors to allow for long-term storage and easy transmission of data.

CT and Laminography

Our industrial x-ray program services are superior and staffed by degreed x-ray inspectors. However, if x-ray is not able to distinguish the characteristics you are looking for, we offer industrial CT scanning and Laminography to yield a measurable 3D volume of your components. Defects can be visualized in 3D and sized/graded according to your requirements.