Laser Tracker Services

3D Engineering Solutions is the premiere 3D Scanning Services provider. Combining a highly experienced engineering staff and the best equipment available, we provide data and engineering output to you in a rapid and cost-effective manner.

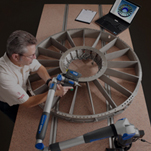

Laser Tracker Alignment Services

3D Engineering Solutions provides metrology grade laser tracker services for all industries, including machine building, installation and fabrication. If you need to precisely align, measure or monitor large-scale objects, this is the technology that is most useful.

Our expected measurement uncertainties are expressed as 20+0.9L microns for the 3-35 meter measurements and 38+1.8L microns for 3-70 meter measurements. This range of approximately 0.0009” to 0.0065” of measurement uncertainty represents the best possible for high accuracy three-dimensional measurements of larger objects.

Combined with precision measurement services from our talented and experienced staff of metrologist engineers, your project will be quickly and correctly completed.

Why 3D Engineering?

We are able to combine multiple technologies with laser tracking to provide the best possible precision measurement services for your large object measuring needs. Our staff of engineers is available to perform a wide variety of services, including reverse engineering.

Large-scale equipment requires fast and competent measurements and alignments. As metrologists trained in multiple technologies beyond laser trackers, we have much experience in all dimensional measurement services requiring high accuracy especially aerospace, space and automotive applications.

What Measurements are Possible with Laser Trackers?

Almost any measurement is possible. Straightness, concentricity, flatness, levelness (and precision leveling), perpendicularity, parallelism and centerline alignment of rotating equipment, to name a few, are all available to be captured with high accuracy laser tracker measurement services.

We can combine laser tracker data with other equipment such as articulating arms and long-range laser scanners to bridge most gaps in measurement ability. If you have CAD models of your machine, equipment or structure, we can also compare the raw data directly to that CAD and present beautiful color maps highlighting and measuring the profile of the equipment (Scan to CAD comparison). If you don’t have CAD, we can create it! Or we can make envelope CAD models to show the profile.

Monitoring of Equipment Settling and Movement

Since laser trackers are so precise, they can be used in conjunction with known monuments or artifacts to monitor the condition of machines and equipment over time (drift monitoring). This digital metrology data allows high accuracy adjustments to be made to keep processes running consistently and smoothly over long periods of time.

This can be extended into deformation analysis. Studying how a large machine or other objects moves over long periods of time is important in many applications. We provide tracker services to customers who ask us to measure their structures during different seasons to understand the actual seasonal size and shape changes or to detect potential creep and deformation.

These seasonal changes are primarily due to thermal growth. When combined with our long-range laser scanning service, we can provide measurement services for short time frame thermal growth issues where contact with the object is not practical or possible.

If your business needs require precision measurements of large objects, reverse engineering or other measurement services, please contact us for a quote!

Robotic Equipment and Machinery Adjustment

Complicated assembly processes require precise equipment alignment and inspection services in order to maintain the needed rates of production and low machine down time. Using laser trackers by themselves or in combination with articulating arms and lasers allows high accuracy measurements over large distances not previously possible.

At 3D Engineering we often employ multiple metrology grade measuring devices in combination to achieve measurement services that would not be possible when using only one type of measurement device alone.

Equipment Modifications

Upgrading or adjusting large complicated equipment can be frustrating. Having the ability to accurately perform an equipment inspection and know dimensional conditions before making adjustments or modifications is invaluable.

Using a laser tracker in our measurement services, we are able to give you live feedback on dimensions and alignments as you make the adjustment. This high accuracy in-process dimensional inspection makes shimming much easier and alignments can be known in real-time.

Our Certifications and ability to Certify and Qualify Machine Tool and Other Equipment

Our laser tracker services are listed in our ISO17025 scope of accreditation. This is the correct ISO certification for dimensional measurements. Our engineering staff are degreed engineers. We choose this route to ensure that our interactions with our customers bring the highest level of technical competence.

Each of our degreed engineers is also certified in Geometric Dimensioning and Tolerancing (GD&T) and cross-trained in all of the technologies that we offer. You can be assured that our equipment is in calibration and our engineers are competent in their use and interpretation of the data.

With any new equipment, your end customer needs to be assured that the machinery is set up correctly and that all equipment alignment has been accomplished. Using our ISO17025 accreditation for laser tracking, you can provide that assurance in a certified and accredited report.

Metrology Applications

At 3DES we are metrologists first and understand the measurements and errors associated with particular measurements. Each feature measured has a certain amount of uncertainty associated with it. We take that into account to help our customers understand the measurements that are taken. We even list our laser tracker on our ISO17025 scope of accreditation and show base level uncertainties.

In addition, the actual feature inspected has a bearing on the measurement. Certain features have more inherent uncertainty than others. We minimize this as much as possible. This goes beyond most precision measurement services who understand how to operate their equipment and take data, but may not have the metrology training to understand how to interpret that data they receive or understand how to properly interpret the original prints.

Our degreed engineers are certified in GD&T and have been trained as metrologists who not only understand the laser tracker but have been cross-trained in each of our other dimensional inspection technologies. We often combine technologies in projects to offer the best combination for our customers.

For laser tracker measurement services work, we can combine laser scan arms and long-range laser scanners to provide the best and most rich set of data possible. Each of our engineers brings a wealth of technical engineering background and practical metrology experience.

Reverse Engineering

Given the high level of accuracy of the laser tracker, these become excellent metrology instruments to use in reverse engineering of larger equipment. This combined with long-range laser data creates an invaluable dimensional inspection tool in reverse engineering efforts.

Our engineers are all versed in one of several CAD packages to take this raw data and create CAD models and drawings to meet your reverse engineering needs. Perhaps it’s one-of-a-kind equipment that needs to be replaced or repaired, or it’s old equipment that has no surviving drawings for reference. We are experts at reverse engineering services and have the correct metrology background and knowledge to efficiently complete your project.

How Laser Trackers Work

A laser tracker is a precision measurement instrument used to measure large objects. For large objects, it is the best technology available to inspect and measure non-simple objects requiring high accuracy.

The laser tracker is a tripod mounted unit that uses a laser distance meter combined with 2 rotational encoders to measure distances. This distance measurement and two angles allow for placing points in a spherical coordinate system to describe the location of features. Each encoder and the laser itself have small amounts of error associated with them.

The best metrology practice is to minimize the use of the 2 rotational encoders by moving the laser tracker unit away from the object and thereby not needing to use a large portion of the encoder range. This minimizes the errors from those encoders. The laser distance measurement is inherently more accurate and so this extra distance away from the object being measured does not add undue inspection error.

Because a laser is used to measure distance to the object, it is affected by temperature changes from the laser tracker to the object. While the laser tracker itself has an internal temperature station it does not know all the temperature variations between it and the object. Externally attached temperature sensors can be used to help mitigate this. Otherwise, if the laser beam travels through a large temperature variance, it will affect the measurement results.

For example, if the measurement has to take place through process steam or past molten metals, you can expect the laser tracker measurements to be affected. Best practice is to avoid these areas and take the measurement from a different direction. Sometimes this is not possible. Elementary calculations can also be taken to estimate these errors and minimize their impact to the inspection if needed.

The actual point data is taken with an SMR (Spherically Mounted Retroreflector). These are hand held devices that must make direct contact with the object being measured. Laser tracker SMRs are not all made equal and some have more errors than others. The amount of error in centering the reflector into the metal sphere is one of the parameters to evaluate when purchasing these.

These values generally vary from 0.00015” (more expensive) to 0.0050” (less expensive) and should be accounted for when that level of precision matters. This assumes that the SMR is in good shape and has not been dropped and damaged. Like CMM probes tips, these spheres can receive damage which changes their spherical shape and affects the measurement results.

FARO provides additional detail and explanation on their “Understanding Laser Trackers” page using examples like their FARO ion laser tracker.

Renting Laser Trackers vs. Hiring Professionals

Laser trackers are available for rent through several sources. For those who are skilled in the art of inspection, this might make the most sense. Most rentals have minimum timing to rent and charge you for the transit time to ship the unit to you and/or back.

For those who are not very familiar with laser trackers and are not seasoned metrologists, be aware that alignment techniques and inspection methodologies appear easy, but are often incorrectly applied. We have seen many instances over the years where measurements taken by those who are not yet trained and skilled with laser tracker technology have been contradicted by correct measurement technique and application.

All of our staff are trained and skilled metrologists and degreed engineers ready to provide the best measurement services possible. We have designed our business model this way to ensure that you receive the best tracker services available in the fastest time. Because of our experience base, we will minimize the time and impact to your operations.

FAQs

-

What does a laser tracker do?

- A laser tracker uses a laser beam to determine the position of an object in three dimensions. Almost any measurement is possible including straightness, concentricity, flatness, levelness (and precision leveling), perpendicularity, parallelism and centerline alignment of rotating equipment.

-

What are laser trackers used for?

- Laser trackers have many applications in industries including machine building, installation and fabrication. If you need to precisely align, measure or monitor large-scale objects, this is the technology that is most useful.

-

What is a laser tracker SMR?

- A laser tracker SMR (Spherically Mounted Retroreflector) is a ball probe with mirrored surfaces used to collect point data. The targeted SMR reflects the measuring laser back to the laser tracker to obtain data.