3D Laser Scanning Services

3D Engineering Solutions provides 3D Scanning Services in Ohio, the US and around the world. We currently have customers in all US states and 14 countries. We have been offering 3D laser scanning services since 2007 and have a large staff of trained, experienced and degreed engineers.

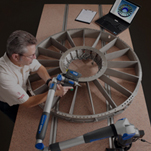

Onsite Laser Scanning Services

Is your project too large to ship to us or is it too sensitive to leave your facility? Then we can come to your site with our equipment and software. We use the best quality portable CMM laser scanners that allow us to work remotely with confidence at your facility. Our expert staff will work around your schedule to accomplish your goals.

What You Can Do With the Data from Our 3D Scanning Services

Laser Scan data is CMM data and can be used for inspection of print dimensions, scan to CAD model deviation color mapping plots, scan to scan deviation color mapping, product troubleshooting and CAD model creation. Our lab is ISO17025 certified for laser scanning. This CMM laser scan data is useful for inspection work and provides you with a permanent record of your part. This digital twin can be used to extract further dimensions not immediately needed and can be used to compare future parts to your current part (scan to scan comparison). You no longer need to maintain a library of first run parts. You can use the laser scan data as your historical record. It doesn’t change with time and can be recalled from anywhere at any time.

Used for reverse engineering projects, laser scan data is excellent in helping recreate one of a kind parts and for competitive analysis. We take this data and create STLs or 3D CAD models in your software of choice for you to use.

Upon request, you can also receive a free viewer in PolyWorks that allows you to see the raw point cloud scan data compared to your CAD. This is useful for web meetings and allows you to rotate the 3D model and data for your customers benefit or to create images for your own customized presentations.

Point Cloud Scanner Price and 3D Scanning Services Cost

Considering your own laser scanner purchase? Consider first using our 3D scanning service as a bridge to your purchase. You get the benefit of an experienced engineer delivering results in the shortest time possible. At the same time, you can evaluate the point cloud data from the project to ensure that a particular laser scanner offers the best value for your needs. A quality laser scanner and software purchase can cost from $50,000 to $100,000 or more. Evaluate the quality of the data using our service and then use that service cost as justification for the equipment, software and training that will be needed for your own laser scanning operation.

Our 3D scanning service cost is derived by having an experienced engineer quote the number of hours that your project will require and then applying internal hourly rates.

3D Laser Scanning Services – How it Works – Laser Design

We use laser line probes that consists of many small laser dots aligned in a row(s). These invisible laser dots are projected onto a surface and read by a camera that is aligned at a small angle to the laser. The laser design allows a high frequency of data collection (up to 500,000 points per second).

Because the laser and the camera are at an angle to each other, there will be spots that are out of the equipment’s line of sight. The camera must see the laser dots in order to register the data. If the laser is projected on one side of a tall rib, but the camera is positioned on the other side, then no data can be collected. This happens with holes as well. The laser can project pretty far into a hole. However, the camera at some point only sees the top surface of the hole due to the required angle. This is a small angle, but does induce line of sight issues in some locations. This is a common feature to all commercially available laser scanners.

Another item to consider is point spacing and spot size. A laser scan does not provide an infinite number of points but rather a very high quantity. The areas in between the laser dots are not captured. The spacing between each laser dot represents the resolution of the scan. The closer the spacing of the laser dots, the better the resolution. For small intricate parts, you need very tight point spacing. Sometimes laser scanning is not the best solution and another technology should be used such as structured light scanning. Each data collection instrument has a spot size. This is the size of the laser spot for laser scanning (for structured light it is the camera pixel size, for fixed CMM it is the contact surface area and x-y-z positioning accuracy, for CT scanning it is the size of the x-ray creation source and digital detector combination, etc). The larger the spot the lower the ability you have to evaluate fine detail. The effect of a relatively large spot size on a small feature is ghosted or intermediary points. These are points in space between two actual surfaces. Basically the spot size is large enough to encompass both surfaces and interpolates the location of the point as somewhere in between. This is most easily seen in long range laser scanners, but can be perceived in many types of light scanners.

3D Laser Scanner Manufacturers

Faro Technologies and Hexagon are the two leading providers of portable laser scanning technology. Nikon and Zeiss are the leading providers of laser scanners that can be added to your fixed CMM. As a service provider we use and/or have been asked to provide feedback on the quality of instruments from each of these. Each piece of equipment has its advantages and disadvantages. The fixed CMM lasers are more accurate but obviously not portable and take longer to program. The portable articulating arm based laser variety is easier to use, to program and to manipulate for unique projects. The fixed CMM lasers offer automation advantages in high volume scanning requirements but less flexibility. If you have an older fixed CMM, you may need some upgrades in order to incorporate the laser.

Laser Scanning Vs. Fixed CMM Scanning

Some fixed CMM probes offer a scanning mode that allows the probe to drag along the surface of the part while it continuously collects data. This is generally a more accurate approach to getting a lot of data for your part compared to laser scanning. However, the coverage of that data is relatively sparse and you must touch the surface of the part. Laser scan data is relatively dense (usually in the millions of points) and is a touchless data collection method. If your surface is very specular (shiny), you may need to apply a light powder or paint for laser scanning. This makes the surface diffuse (light scatters equally in all directions) which is optimal for laser scanning. If you cannot touch the surface or apply a paint/powder (potential FOD), then you must look into another technology (CT scanning for example). The laser scanner manufacturers continually improve their products to be able to scan more specular surfaces, but there still is sometimes a need for a paint/powder to reduce the amount of noisy data.

Training for 3D Laser Scanning Services near Me

If you have your own equipment, 3DES can come and train your staff onsite. Our training is one set price for as many of your staff as you wish to attend. However, fewer staff equals more one on one training time. We train to your parts and your prints not to a ‘standard’ part or training book. In this way, you can see how we develop your inspection process and resolve measurement challenges from the beginning to the end. Each trainer is experienced in GD&T and has read and interpreted hundreds of prints at a minimum.

3D Engineering solutions also provides programming services for laser scanning. Use our experience to jump start your newly trained staff in their work. We generally require a print and a copy of your part so that we can program and test the 3D scanning here in our Cincinnati Ohio office.

FAQs

What are Laser Scanning Services?

Laser scanning services involve using laser technology to capture detailed spatial information, creating precise 3D models or representations of physical objects and environments. These services find applications in various fields, including architecture, reverse engineering, construction projects, and more.

How Accurate is Laser Scanning?

Please contact us today for all your 3D Laser Scanning requirements.

Contact us today for all your 3D Laser Scanning requirements.

Related Services