Color Mapping Technology for First Article Inspection

As part of our ISO 17025 quality inspection services at 3D Engineering Solutions, we now provide color mapping technology for first article inspection of cast parts, a service many other engineering firms still do not offer. Color mapping provides qualitative illustrations that show the difference between a scanned object and its nominal design. We provide different types of analysis for our customers, giving them both quantitative and qualitative data. This saves time and money in the qualification process and makes it easier for our clients to get parts to their customers.

|

|

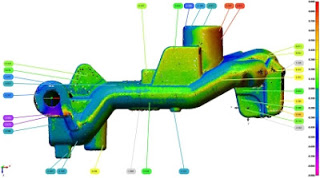

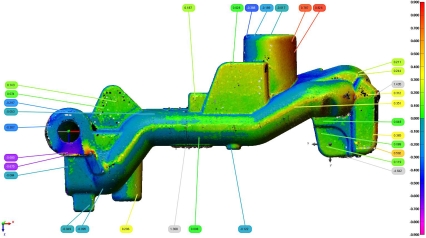

Color map showing object scanned and

compared with CAD model and then highlighted with PolyWorks point cloud software to show differences between scanned part and nominal design. |

We primarily use portable CMM (Coordinate Measuring Machine) laser equipment and precision structured blue light scanning to collect part data. We also use industrial CT scanning to capture non-‘line of sight’ or internal features and long range laser scanning to provide ‘as built’ comparisons for bridges, buildings and other large objects. Each data collection method then uses PolyWorks point cloud software by InnovMetric to create the color maps.

As part of our services we deliver the ISO 17025 certified reports in multiple formats to accommodate various quality systems, including Production Part Approval Process (PPAP) and AS9100 requirements, for example.

Leave a Reply

Want to join the discussion?Feel free to contribute!