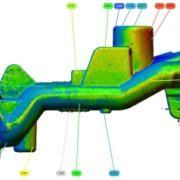

What Is the Reverse Engineering Process and How Does It Work?

How Does Reverse Engineering Work?

Reverse engineering is the process of analyzing and deconstructing something to see how it works. An example would be taking apart an alarm clock to understand what each piece does – and how the pieces work together.