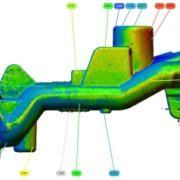

What Is Metrology and Why Is It Needed?

What is Metrology and Why is it Needed?

Metrology is the scientific study of measurement. This field of study defines measurements under a common understanding, applies these measurements in practice, and uses them in analysis across industries. Because of its broad applicability, metrology is used worldwide to establish accuracy and precision in many critical fields.