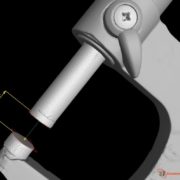

Common Contact Measurement Devices and Methods

Contact measurement devices constitute the majority of what is traditionally used for dimensional metrology. These consist of devices that must be in physical contact with the object to be measured. Below is a listing of general types of contact measurement devices. This covers the vast majority of what is used today and is a good overview on what is possible and what to expect from data taken with these instruments. We freely use these types of devices in our service business where it makes sense for any particular project due to quality, cost and timing.