3D Scanning Services

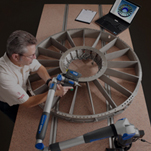

3D Engineering Solutions is the premiere 3D Scanning Services provider. Combining a highly experienced and degreed engineering staff and the best equipment available, we provide data and engineering output to you in a rapid and cost-effective manner. We offer 3D scanning services and other engineering and quality control services such as inspection, first article inspection (FAI), and reverse engineering. Find a great solution today!

What is 3D Scanning?

3D Scanning predominantly involves touchless methods to collect physical data from an object. This can also refer to touch probe scanning done with fixed Coordinate Measuring Machines (CMM). In the latter case, scanning refers to dragging the touch probe across a surface while continually taking data. This dragging process generates a point cloud on the order of magnitude of 10s of thousands of points. Touchless versions of 3D scanning equipment yield point clouds in the millions or 10s of millions of points.

3D Long-Range Scan of the Roebling Suspension Bridge with color information

Because of 3D Scanning’s relatively high point density, it is typically superior to single-point CMM probing and data collected by hand tools. Touchless methods of 3D Scanning have the advantage of not disturbing the object being measured. This is especially helpful for flexible or delicate structures.

Fixed CMM touch probes (used in a scanning mode or single point mode) are generally more accurate than touchless methods. However, due to the physical contact, they may damage delicate or easy to scratch surfaces.

How accurate is 3D Scanning?

This is dependent upon the exact 3D scanning technology used. For touchless 3D Scanning, the accuracy typically starts at 0.0002” and goes to about 0.0035”. For long-range laser scanning the accuracy is usually in the 0.0800” range or worse. Contact probe scanning accuracies are usually in the 0.0001” to 0.0003” range.

When assessing quotes for 3D scanning services, be sure to understand the measurement uncertainty of the equipment that is being proposed. This is different from the equipment’s accuracy and includes factors that the manufacturer’s accuracy does not include. Note that both accuracy (and by extension measurement uncertainty which is based on the accuracy) is always listed at +/- 2 sigma. You will want a TUR (test uncertainty ratio – the tolerance you are looking for divided by the measurement uncertainty) of ideally 10:1. Many will accept a TUR down to 4:1. This basically means that the equipment being used is 4 times better than the tolerance you are looking for (4:1).

Because of the extremely tight tolerances found in products today and limits in the state of the art technology, we have even seen TURs of close to 1:1 being acceptable!

Please contact the reverse engineering professionals at 3D Engineering Solutions with your 3D scanning project’s specific requirements and we will be able to show you what is possible!

How much does it cost?

The answer to this lies in the scope of the work involved. We quote work by having one of our degreed engineers estimate the time to complete the particular scope of the 3D scanning project along with standard project requirements and then apply internal rates. More detail about what you are looking for will allow us to define the scope more precisely and give you the best value / lowest cost quote. Most of our quoting is accomplished through seeing digital images of the object. From those images and our large experience base, we can estimate scanning times and times for other engineering services such as inspection, first article inspection (FAI), or Reverse Engineering.

We have quoted scanning work for as low as $20 per part and more than $100,000 per 3D scanning project. Most jobs range from $500 to $7,000. The amount of post processing work done with the scan data such as dimensional extraction and modeling will affect this value.

We typically turn quotes around within a day. Please have us quote your 3D scanning project!

Our 3D Scanning Systems

Since no one 3D scanning service or device is suitable for all applications, we are constantly adding to our toolbox as new technology and improvements become available. We employ all the major scanning technologies including laser scanning services including both long-range laser trackers and short-range laser trackers, blue light scanning, white light scanning, photogrammetry, confocal white light scanning, metrology services, scanning probes, industrial x-ray services, and industrial CT scanning. Learn more about other systems like white light scanning (link).

Each of our staff members are degreed engineers or/and NAS410 certified in CT scanning. All have been trained in each technology and software that we use. So each understands the trade-offs between each scanning technology. We ensure an adequate scanning capacity for your requirements by having multiple pieces of equipment for each scanning technology and a nimble and flexible staff that can properly obtain quality data.

3D Scanning File Formats

The raw output of most scanning devices is a point cloud. These are points in space defined by an XYZ location, an IJK vector direction (indicating the surface normal direction), and sometimes color information. Point clouds can be a few hundreds of points to millions of points in size. This original raw data is not useful for industrial CAD programs in general (although Autodesk products including Revit can handle these easily). These points are seen by most CAD programs as individual entities and therefore can quickly bog down even the largest computers.

3D Scan – STL with color information

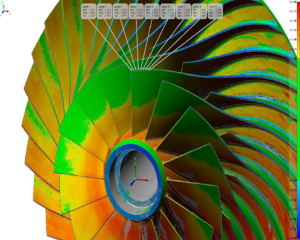

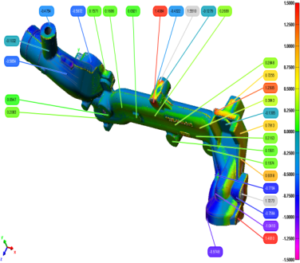

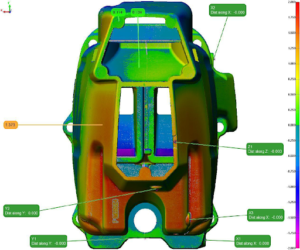

Raw point cloud data compared to CAD models – Heat Color Mapping

Contact us for more options of file format outputs. We are here to help you be successful!

Can a scan of a physical object be directly converted to a CAD model?

This is one of the most common questions asked of us concerning our scanning services. Many assume that the scanning process is also a modeling process. Unfortunately, the state of the art technology does not allow this. There is work being done in this area to move closer in this direction where it could be possible in the future for large objects like entire buildings can be directly converted. Currently, the best way to obtain a CAD model is to first convert the data to an STL file and use that as a basis for creating a model in CAD manually. You could also create primitive shapes (planes, cylinders, circles, etc) in certain software that can be brought directly into CAD as STP, IGS, or Parasolid files to aid this.

Our staff of reverse engineering professionals is well trained and experienced in translating raw scan data into fully parametric or surface models. Because this is a large part of our business, we have become very quick at doing so. Consider outsourcing this portion of your work with us to help improve your internal throughput. In most cases, we can accommodate rapid prototyping and creating the models in your specific CAD platform!