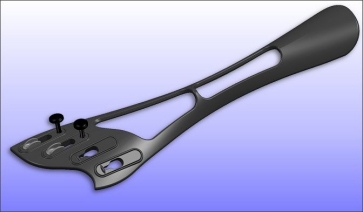

3D Laser Scanning and CAD Modeling Bring High Tech Violin and Cello Tailpieces to Market

Using 3D laser scanning and CAD modeling technology, 3D Engineering Solutions helped The Frirsz Music Company bring its patented violin and cello tailpieces that improve sound and performance to the marketplace. These lighter than wood tailpieces comprised of aerospace metal alloy can now be manufactured for musicians everywhere because of the 3D scanning services and design expertise provided by 3D Engineering Solutions.

The original tailpieces underwent precision scanning, which captured the objects’ high-density geometry and compound surface curvature. 3D Engineering’s 7-axis, laser measuring devices and specialized software allowed engineers to collect data as millions of points and create point cloud files. That data was then used to generate highly accurate 3D CAD models of the violin and cello tailpieces.

“To have an opportunity to replicate in 3D CAD one-of-the-kind violin and cello tailpieces is a great example of bringing an entrepreneurial vision to life,” noted 3D Engineering Solutions VP of Operations, Rob Glassburn. “We helped bridge the gap between inventor and production company, with the assistance of our CAD engineering team.” Senior 3D CAD Engineer Gene Hoppe’s experience in designing tools and fixtures in the automotive and aerospace industry provided the necessary skills to handle some of the complex manufacturing issues of this project such as draft, temperature coefficients, and material selection.

Leave a Reply

Want to join the discussion?Feel free to contribute!