Quality Inspection Services

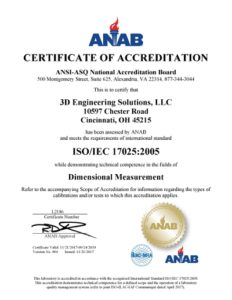

3D Engineering services is ISO 17025 Certified

By letting us measure your product and create a virtual model, you’ll receive an accredited level of inspection that ensures the quality of your product. A product that goes through our assessment has an industry approved level of accuracy. That accuracy ensures your product can be seen with the highest level of quality.

PPAP Quality Support & First Article Inspection

We can greatly enhance the dimensional inspection aspects of your Production Part Approval Process (PPAP) and first article inspections with our portable CMM and other digitizing capabilities. Our ISO 17025 certified inspection process enables the collection of more dimensional data in less time, including full modeling of parts. 3D Engineering Solutions also provides customized, ISO-certified reports in multiple formats to accommodate your quality systems and certification programs such as SAE AS9102, ISO/TS 16949 and QS 9000.

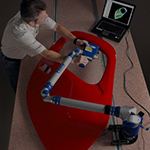

Direct Scan to CAD Comparison

At 3D Engineering Solutions, we provide full dimensional inspection services to 3D models with our advanced digitizing equipment. This allows direct scan-to-CAD model comparison, enhancing the inspection and reporting process for parts, gauges, and fixtures associated with your production operation.

Click here to see sample Inspection Report (PDF format)

Click here or on the image to the right to download our ISO17025 scope from ANAB