3D Scanning Services

3D Engineering Solutions has gained a wealth of knowledge working with our clients’ scanning needs. Utilizing a variety of different technologies and recognizing the advantages and disadvantages of each, we can offer one or multiple 3D scanning services that best suit you.

Our staff has experience working closely with our clients to ensure that the most accurate digital dataset model of your project is captured and high-value deliverables are produced. We have worked with manufacturing experts for years, and understand the importance of a reliable scan. From CAD models and inspections, to rapid prototyping and reverse engineering services, we are equipped to serve any situation.

Whether it’s for automotive parts, mechanical assemblies, complex geometric objects, or entire buildings, we have the technology and expertise to guarantee an accurate scan. We are always open to a challenge and embrace the opportunity to solve scanning issues that other companies aren’t capable of solving or cannot handle.

Types of 3D Scanning Services We Offer

At 3D Engineering Solutions, we do not just offer one 3D scanning service, but many scanning services! All 3D scanning services are not equal and each has advantages and disadvantages depending upon your application. We tailor each project’s requirement with the best equipment available to give you outstanding results. We cover:

- Long-range 3D laser scanning

- Short-range 3D laser scanning

- White and blue light structured light scanning

- Confocal white light scanning (splitting white light into its frequencies/colors to measure by)

- Industrial CT scanning

Several of our technologies are portable and able to be taken at any location across the globe.

3D Laser Scanning Technology

Each 3D scanning technology that we employ has certain characteristics that make it better for particular projects than others.

Structured light scanning (both blue light and white light) is ideal for high-resolution requirements around reverse engineering and high-level detailed inspections.

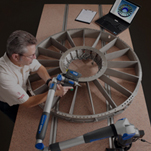

Short-range 3D laser scanning on an articulated arm allows complex access to hidden features and offers extreme portability with many mounting options (clamp, tripod, magnetic mount, vacuum mount).

Confocal white light scanning can directly measure highly specular (up to mirror surface) and transparent surfaces without surface preparation (powders or paint).

Long range 3D laser scanning brings the world of large physical objects into reach for easy measurement.

Industrial CT scanning stands at the pinnacle of 3D scanning technology with the ability to not only see hidden areas in high detail, but also inside the base materials of the objects to see porosity, delaminations, inclusions, and other defects.

Whichever scanning technology or combination of multiple technologies you need for your project, 3D Engineering Solutions has a solution for your needs.

Point Clouds and Voxel Data Sets

We are experts at collecting point cloud and voxel (CT scanning) data sets and then using that data for various engineering activities such as:

- Reverse Engineering

- Inspection

- Troubleshooting

- Comparison

- CAD Modeling

All of our staff members are degreed engineers who are well versed in geometric dimensioning and tolerancing (GD&T) and each data collection technology that we employ. They are well-suited to interact directly with your engineers and technicians. Our team is comprised of metrologists who enjoy the diversity of projects and problems that our customers bring us to solve.

Reverse Engineering

Whether your needs involve repairing a mold or die that has broken unexpectedly, creating design documentation like CAD files, models, or drawings for a product that existed before the digital age, or making improvements to an industry starting with the existing technology as a baseline, we can help. We have all of the tools, technologies, and experience to ensure accurate processes and results.

Inspection

Our lab is ISO17025 accredited for most of the technologies that we employ, including industrial CT scanning. We pair all of our scanning technologies with good traditional vision, CMM, and common hand gages to provide unparalleled inspections and detail-oriented inspection reports.

Since we understand our equipment and processes so well, we can work past common errors that can come from each unique scanning technology. And we know when not to use 3D scanning technologies in favor of simple 1D gages! Sometimes, those are the better tools to use for the best accuracy and cost.

Troubleshooting

Our depth of engineering background in various fields places us in a unique position to offer troubleshooting aid to your staff. We can offer you solutions based on our experience and knowledge of the technologies we employ that you may not have thought of before. Just give us your end goals for the project and we will help brainstorm the most efficient path to get the data that you need.

Comparison

3D Scanning technologies offer an unmatched ability to compare like parts to each other or to ideal CAD models. A scan-to-scan comparison allows a high-resolution comparison of millions of points of data between two like parts.

This is useful for understanding differences between part suppliers at a moment in time, between one supplier over a long period (i.e. an FAI part compared to the same part produced year(s) later), or exemplar parts to actual components in dispute.

Likewise, a scan-to-CAD comparison allows you to see how a manufactured part deviates from the original design intent. You can now visualize the deviations over the surface of the actual manufactured parts and gain a good understanding of those effects on the overall design.

CAD Models

Taking raw point cloud and voxel scan data and transforming that into CAD models is a common activity for 3D Engineering Solutions. Our degreed engineers are experts at taking the scan data of complex parts and surfaces and creating well-fitting parametric, non-uniform rational B-splines modeling (NURB), and hybrid CAD models.

The reverse engineering process usually involves creating a polygonal model first (typically a . STL file) and then using that as a basis for CAD models using native features of your favorite CAD package. We currently create these models in NX, SolidWorks, CREO, and Revit. We work with your engineering department to understand if you require ‘as built’ models or ‘design intent’ models. We stand ready to help you with your CAD modeling needs.

FAQs:

Are 3D Scanners Worth It?

The worth of 3D scanners depends on various factors such as your specific needs, budget, and intended applications. They can be invaluable for industries like manufacturing, engineering, healthcare, and architecture, enabling precise measurements, quality control, reverse engineering, and design enhancements.

How Accurate is 3D Scanning?

The accuracy of 3D scanning varies depending on factors like the type of scanner, scanning technology, and the object being scanned. High-end scanners can achieve sub-millimeter accuracy, suitable for precision engineering and quality control applications. However, lower-cost scanners may have less accuracy, making them more suitable for less demanding tasks like hobbyist projects or basic modeling. Overall, modern 3D scanning technology offers impressive accuracy, but it’s essential to choose the right scanner and settings for your specific needs.

What Does it Cost to 3D Scan an Object?

The cost of 3D scanning an object can vary depending on factors such as the size and complexity of the object, the level of detail required, the type of scanner used, and the service provider’s pricing structure. Generally, small and simple objects may cost less to scan compared to intricate or large physical objects. Additionally, the expertise of the technician performing the scan and any additional services required (such as post-processing or data manipulation) can also influence the overall cost. It’s best to consult with a scanning service provider like 3D Engineering Solutions for specific pricing based on your project requirements.